|

| |

|

| |

46, Vishal Industrial Estate, Near Ceat Tyre, Village Road, Bhandup (West), Mumbai - 400078.

Mob. No. : 91 - 8879948316,9820054305

|

|

| |

|

|

|

| |

Creamic Band Heaters |

| |

|

| |

|

| |

Hotwatt's Ceramic Band Heaters are developed keeping in mind the requirements of the industry for high temperature long lasting heaters. The HOTWATT Ceramic Heaters are specifically designed to replace and upgrade your Mica Band Heaters on your Injection and Extrusion machines. The body of the Ceramic Band heater is constructed of precision made segmented ceramics, which add flexibility and allow for easy installation. The ceramics are covered with insulation, which serves to lower the shroud temperatures and concentrates the heat towards the barrel. The end results are less wasted energy, a lower wattage requirement and a longer heater life. We specialize in customizing the heater to meet the customer’s need. |

| |

Applications:

• Injection Moulding.

• Blow Moulding.

• Film extruders.

• All Plastic & Rubber Processing Machinery.

• Pipe and drum heating

• Ideal for use on Injection and extrusion barrels (when processing low, medium and high temperature resins)

• Tank Heating

|

| Ceramic Band Heaters – Features |

| Available in Chrome Nickel Steel with Power Saving options |

Easy Installation and Removal |

| Special High Grade Steatite Insulators for Superior Thermal Conductivity. |

S.S Steal Terminal Junction with Specially Designed Protection Cap. |

| Power saving up to 30%. |

Efficient Heat Transfer even on irregular surfaces. Heating efficiency upto 40 W/inch² |

|

| |

| CREAMIC BAND HEATER - TECHNICAL DATA |

| Outer Sheath Material |

Polished S.S.304 |

| Heating Element in Coil |

NiCr 80:20 |

| Surface Loading |

20-40 W / inch2 |

| Termination |

Metal Braided Fibre Glass wires |

| Insulation |

Flexible Asbestos sheet or Ceramic Fibre covered with Aluminum foil to avoid black spots on outer sheath. |

| Resistance Tolerance |

± 5% |

| Minimum Diameter |

40 mm |

| Minimum Width |

34 mm |

| Nominal Heater Thickness |

12 mm |

|

| |

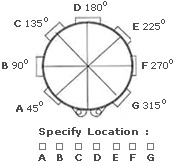

| Terminal Location |

|

|

|

| NOTE: Unless specified, The Terminal Location will be at 180°C opposite to clamping. |

| |

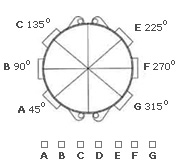

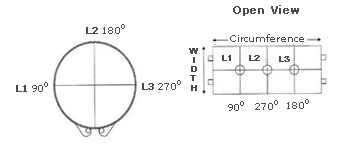

| Thermocouple Holes Location |

| T/c holes at center of width for Single Piece |

|

|

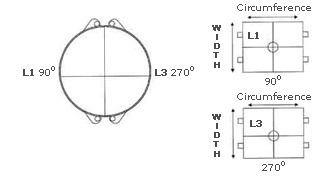

| T/c holes at center of width for Two Piece |

|

|

| |

|

|